For years, the world of coding and marking on flexible packaging has been dominated by continuous inkjet (CIJ) and thermal transfer overprint (TTO) technologies. While these methods serve their purpose, a new technology has emerged, offering a superior level of flexibility and adaptability: Thermal Inkjet (TIJ) printing.

This shift is not merely a change in machinery but a leap towards efficiency, precision, and versatility. In this post, we delve into how TIJ technology is revolutionizing the coding process on flexible packaging lines, including Vertical Form Fill Seal (VFFS), Horizontal Form Fill Seal (HFFS), and winder-rewinders, among others.

From Continuous Streams to Precise Drops: The Evolution of TIJ Printing Technology in Flexible Packaging

Traditionally, CIJ and TTO held the reins in flexible packaging printing. However, TIJ technology has been rapidly advancing, bringing significant advantages to the table:

- Unmatched Versatility: TIJ printers boast the remarkable ability to be seamlessly integrated into any flexible packaging line, be it Vertical Form Fill Seal (VFFS), Horizontal Form Fill Seal (HFFS ), or winder rewinders. This adaptability is crucial for manufacturers looking to upgrade their packaging lines without extensive modifications.

- High-Speed Precision: Modern TIJ printers maintain exceptional print quality even at high production speeds. This ensures crisp, clear barcodes that meet even the most stringent resolution requirements.

- High-Speed Precision: Modern TIJ printers maintain exceptional print quality even at high production speeds. This ensures crisp, clear barcodes that meet even the most stringent resolution requirements.

- Embracing Technological Advancements: The evolution of TIJ doesn’t stop at printing prowess. These devices now incorporate features like Wi-Fi connectivity, allowing for remote monitoring and operation.

- Ink Innovation: The world of TIJ inks has witnessed significant developments. New formulations offer superior adhesion to various flexible films, ensuring the longevity and readability of printed codes. Additionally, these inks deliver high-resolution printing, further enhancing the capabilities of TIJ systems.

- Reduced Maintenance Costs: Unlike CIJ and TTO, TIJ printers boast near-elimination of extensive maintenance requirements. This translates to significant cost savings in the long run.

- Cost-Effective Consumables: TIJ systems do away with the need for frequently replacing expensive ribbons or ink cartridges used in TTO printers. This translates to substantial savings on consumables.

- Intuitive Software with Production Monitoring: TIJ printers come equipped with user-friendly software offering valuable features like daily and hourly production reports. This allows manufacturers to effectively monitor their output and optimize their production processes.

- Remote Upgradability: TIJ software boasts the advantage of field upgrades. These upgrades can be implemented remotely, eliminating the need for engineer visits to the production plant, minimizing downtime and ensuring the system remains updated with the latest advancements.

- Enhanced Connectivity: TIJ integrates seamlessly with third-party devices like PCs or PLCs through its auto-pilot function. This enables real-time monitoring, operation, and data exchange, fostering a more automated and efficient production environment.

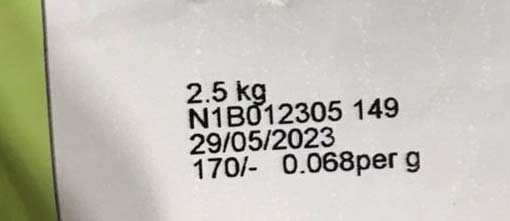

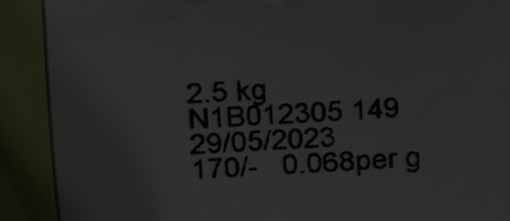

- Variable Data Printing: TIJ printers excel at incorporating online variable external data into their printing. This allows for dynamic printing of crucial information like batch numbers, expiry dates, and other critical details directly

As TIJ technology continues to evolve, its role in flexible packaging coding is set to grow even more significant. With ongoing improvements in print speed, resolution, and ink formulations, along with the potential for further integration into smart manufacturing processes, TIJ is paving the way for a future where coding is no longer a bottleneck but a driver of efficiency and quality.

In conclusion, the adoption of Thermal Inkjet technology in the coding of flexible packaging represents a forward-thinking approach to overcoming the limitations of traditional methods. With its unmatched flexibility, high-speed and high-resolution capabilities, advanced connectivity, and innovative ink solutions, TIJ technology is setting a new standard for excellence in the industry. As manufacturers continue to embrace these advancements, the future of flexible packaging coding looks brighter—and more efficient—than ever.

Recent Comments